The most critical area in continuous casting is where the liquid steel turns into solid form. This is where the mould and related technologies come into existence to achieve successful and high-quality castings. OSIM with decades of experience in moulds and surrounding technologies, will direct you to the best solutions for success.

Productivity, operation and billet-quality are influenced to a large extend by the efficiency of the copper moulds. High speeds of > 4 m/min require intensive and uniform heat-flux which can be achieved with innovative mould design.

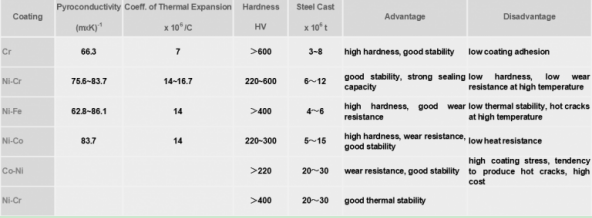

Extra-long service-life is achieved with the special OSIM multi-layer Ni-Co-Cr coating, which features high micro hardness and optimum binding strength with the copper base.

The idea to apply an intermediate layer of Ni-Co has the focus to increase mould life avoiding the formation of cracks in the Cr layer, especially at the meniscus.

The Ni-Co, in fact, has a coefficient of thermal expansion that is almost half way between thermal expansion coefficients of copper and Cr.

Therefore, the Ni-Co coating is better able to tolerate the greater expansion of the copper that takes place in the meniscus area during the casting process.

The presence of the Ni-Co prevents the contamination of the copper substrate with components from the molten steel and/or casting lubricants such as sulphur or zinc, hence avoiding for example brass formation.

Comparative field tests in a number of steel plants have confirmed a significant increase in the average life of mould tubes plated with the Ni-Co-Cr coating.

OSIM tubes are designed for maximum heat transfer rate from the meniscus down to the bottom of the tube. The taper-geometry depends on the steel-grades and casting conditions and is designed with the aim of minimizing the gap between the solidifying shell and the copper tube.

Advantages of OSIM Mould-Tubes:

High casting speed

Uniform shell growth

No sticking

Optimum billet quality

Long service life

Low cost

For high casting speeds OSIM has developed and designed the copper tubes with extended length which are operating very successfully at a major steel-producer.